Unleash the full potential of blue hydrogen

Low-carbon or blue hydrogen is key to the energy transition. Blue hydrogen technologies offer the opportunity to affordably decarbonize hard-to-abate industries and power as well as heavy transportation at the scale needed to meet growing energy demands.

BlueH₂ by T.EN™: The complete low-carbon hydrogen solution

From technology to design, delivery and beyond, BlueH2 by T.EN™ is a unique suite of fully integrated, low-carbon hydrogen technology and EPC solutions, part of Capture.Now™, our strategic platform for all our CCUS solutions tailored to meet our clients’ decarbonization and performance needs.

With BlueH2 by T.EN™, we can deliver the best possible levelized cost for blue hydrogen production with the lowest carbon footprint across any type or scale of plant.

Optimize your decarbonization strategy

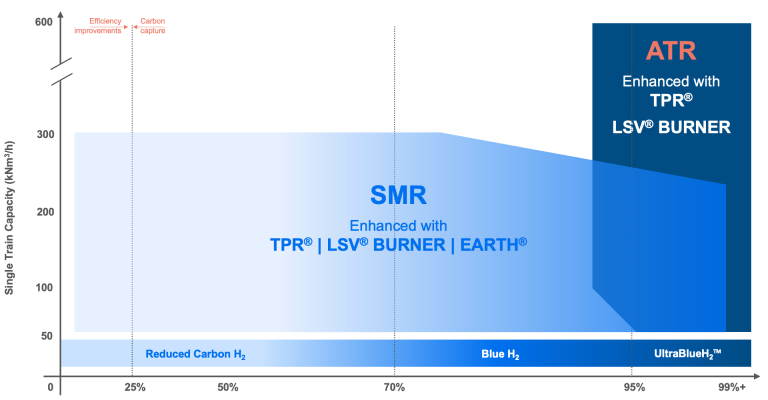

Technip Energies is your technology and project delivery partner for your decarbonization strategy including the production and use of low-carbon hydrogen. By combining proprietary reforming technologies (ATR-TPR/SMR/POX) and carbon-capture solutions for up to 99% capture rate with more than 60 years of project delivery experience, we design and deliver best-in-class low-carbon hydrogen projects. We help our clients achieve their decarbonization ambitions through revamping their existing units or delivering their grassroot facilities.

Leveraging our advanced BlueH2 by T.EN™ suites of technologies and expert services, we use a tailored approach to provide you with the hydrogen you need.

Proprietary ATR technology for large-capacity, ultra-blue hydrogen

As a global leader in hydrogen, we have added Oxidative ATR technology in partnership with Casale to our extensive range of proprietary SMR technology solutions to deliver large-capacity, ultra-blue solutions with up to 99+ percent carbon capture rates.

The oxidative reforming process - Auto Thermal Reforming (ATR) and Partial Oxidative (POx) - produces syngas that contains hydrogen, CO and CO2. ATR combined with Technip Parallel Reformer (TPR®) and carbon capture is a cost-effective way to produce low-carbon hydrogen with optimized steam production. A game-changing technology, ATR breaks the upper capacity limit of traditional hydrogen plants.

Industry leading steam methane reforming (SMR) technology

SMR is well suited to a wide range of capacities and we have unrivaled experience in this area with more than 275 hydrogen plants using our SMR technology. We can deliver top-fired reformers for hydrogen plants up to 300 kNm3/h (1 GW) in a single unit with optimized CAPEX and the lowest plot requirements without compromising OPEX.

The value unleashed by BlueH₂ by T.EN™

Unleash up to 99+ percent carbon emissions capture

99+ percent reduction in the carbon footprint compared to the traditional hydrogen process – from ~10 down to <0.1 kilogram CO2 per kilogram H2.

Unleash more than 99 percent operational reliability

Our hydrogen plants have proven reliability and demonstrated onstream availability of more than 99 percent for uninterrupted hydrogen production.

Unleash more yield and the best LCOH

Maximum hydrogen yield, minimum energy demand (fuel + power), and highly efficient carbon avoidance and CCUS techniques to arrive at the lowest levelized cost of low-carbon hydrogen production.

Unleash added value

Increase your profits with the coproduction of value products, such as steam, synthesis gas, CO, power and derivatives.

low-carbon hydrogen plants and reformers

years of leadership in hydrogen production

references with CO2 capture in H2 plants

of existing installed capacity worldwide

The optimum solution for any type or scale of hydrogen application

BlueH2 by T.EN™ comprises the proven building blocks needed to deliver the optimal blue hydrogen production process, regardless of plant feedstock, reforming type, plant capacity or industrial application.

In addition to serving the traditional grey and blue hydrogen business, we are evolving our technology to refining and chemical manufacturing and to the decarbonization of industries including steel, cement, power, olefins and LNG as well as facilitating clean energy carriers. As the energy transition gathers pace, BlueH2 by T.EN™ is making a vital contribution.

Fully integrated performance

Our core SMR and ATR technologies, combined with our performance optimization and gas processing expertise, ensures that T.EN designs and delivers a fully integrated solution with an optimum flowsheet for any application.

ATR and SMR technologies

Hydrogen plants with overall CO2 capture rated up to 99+ percent are achievable using pre-combustion process capture with our flowsheet and technology solutions.

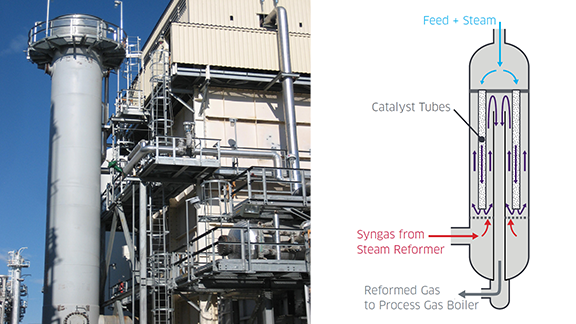

Recuperative reforming solution that saves 30 percent on fuel costs and reduces CO2 emissions by 10 percent. Fully proven in operation and can be installed in existing and new reformer tubes with simple drop-in (minimum CAPEX).

Our proprietary convective recuperative heat exchange reformer is designed to optimize the high-grade heat cycle (reduce CO2 emissions by up to 20 percent), reduce hydrocarbon consumption and increase reforming capacity by up to 30 percent. Successfully operating for over 20 years with installed capacity up to 160 kNm3/h and growing.

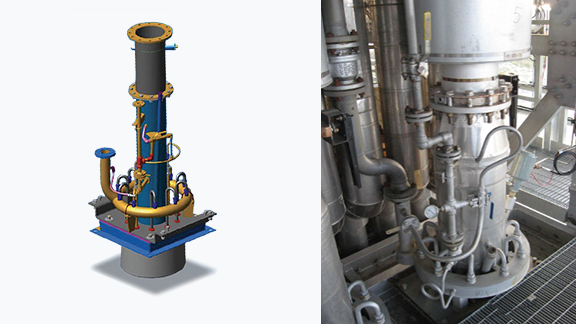

LSV®: Large-scale Vortex ultra-low NOx burner

Our proprietary ultra-low NOx burner technology delivers flameless combustion and is suitable for a wider range of furnaces and fuels. Recently tested with 100 percent H2 firing. Adjustable and uniform flame heat release to enhance furnace performance.

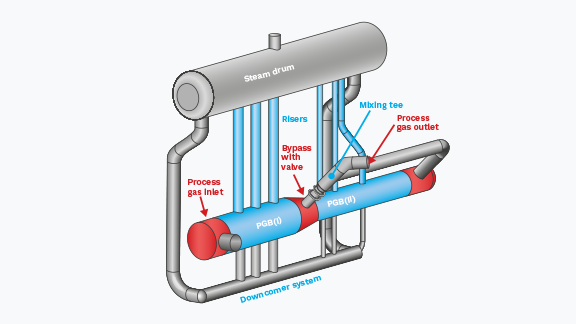

Dual-chamber process gas boiler

Our proprietary dual-chamber process gas boiler enhances cost-effectiveness and improves energy efficiency through extended heat recovery.

Cost, performance and schedule certainty

BlueH2 by T.EN™ combines our proprietary technology with more than 60 years of project delivery experience to provide you with the best-levelized cost of hydrogen. From feasibility studies and technology to turnkey plant delivery and startup, we guide you every step of the way.

We take full responsibility throughout the entire process to give you cost, performance and schedule certainty. Our customized solution allows your hydrogen production to evolve to your changing decarbonization and operational needs.

With BlueH2 by T.EN™, we deliver solutions to meet your hydrogen decarbonization strategies from small (10 kNm3/h) to mega (1,000 kNm3/h) in new builds or revamps of existing plants.

Delivering reliable and efficient plants

We deliver low-carbon hydrogen plants with the highest levels of reliability and efficiency in the industry, constantly pushing boundaries for more than 60 years to unleash the full potential of blue hydrogen.

- Exxon Mobil Baytown, awarded FEED for the world’s largest blue hydrogen project with ~1 billion cubic feet of low-carbon hydrogen production per day and 7MT of associated CO2 emissions captured.

- LG Chem, the first BlueH2 by T.EN™ plant to supply Daesan complex in South Korea with a 56 kNm3/h with 250,000 TPA CO2 capture.

- TG Blue Bison DOE, pre-FEED / FEED for 245 kNm3/hr blue H2 with >97% CO2 capture.

- Tallgrass Energy, technology comparison ATR versus SMR enabling >90% CO2 capture – BlueH2 by T.EN™.

- Sinopec refinery and Acetic Acid facility, China, multi-product HyCO plant with 100% pre-combustion CO2 capture.

- HPCL Visakh, India, two hydrogen trains with a combined capacity of 320 kNm3/h, comprising the largest hydrogen generation plant in India. The project includes power generation from the hydrogen plant as well as Technip Energies proprietary recuperative reforming technology TPR® that reduces CO2 footprint per unit of hydrogen.

- Suncor Refinery, largest single train H2 plant in operation, 223 kNm3/h + 75 MW.

Additional information and downloads

FAQ

Blue hydrogen is produced from natural gas through a reforming process using steam methane reforming (SMR), auto thermal reforming (ATR) or partial oxidation (POx). During the reforming process, carbon is captured and stored to reduce hydrogen carbon intensity, making blue hydrogen technology a cleaner and more environmental alternative to grey hydrogen production, which does not capture greenhouse gas emissions.

Blue hydrogen is low-carbon hydrogen produced from natural gas with carbon capture and storage (CCS), while green hydrogen is produced through water electrolysis using renewable electricity. This hydrogen production method results in near-zero carbon dioxide emissions, making green hydrogen a clean and sustainable energy source to generate electricity and power vehicles.

The advantages of blue hydrogen production include lower carbon emissions compared to grey hydrogen, efficient use of existing natural gas infrastructure and immediate availability at large scale through proven technologies. Blue hydrogen technology serves as a transitional energy source toward a more renewable hydrogen economy, powering the energy transition and boosting global environmental climate goals to reduce fossil fuel reliance. O2 emissions by up to 20 percent), reduce hydrocarbon consumption and increase reforming capacity by up to 30 percent. Successfully operating for over 20 years with installed capacity up to 160 kNm3/h and growing.

Get in touch

Unleash the opportunity of blue hydrogen

Discover how BlueH2 by T.EN™ can help you efficiently and affordably achieve your hydrogen decarbonization goals, on any scale, fast.