Decarbonized and affordable solutions for hydrogen production

Blue hydrogen, or low-carbon hydrogen with substantially reduced CO2 emissions, is produced through minimization of the primary carbon footprint and deliberate capture of the coproduced CO2.

Unleash the full potential of blue hydrogen with BlueH₂ by T.EN™

From technology to design, delivery and beyond, BlueH2 by T.EN™ is a unique suite of fully-integrated, low-carbon hydrogen technology and delivery solutions from a single provider tailored to meet our clients’ specific decarbonization and performance needs.

Capture 99% of your blue hydrogen production emissions

Featuring carbon capture rates of 99+ percent, BlueH2 by T.EN™ combines our proven suite of ATR and SMR technologies with our extensive hydrogen experience to deliver the best possible levelized cost for blue hydrogen production with the lowest carbon footprint across any type or scale of plant.

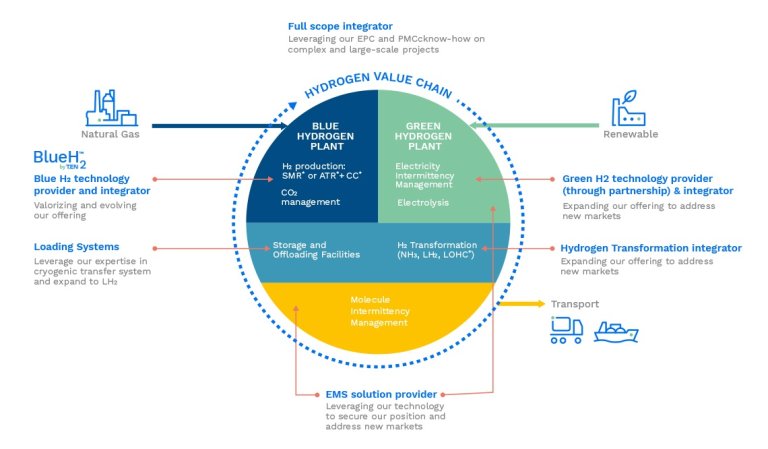

Our positioning across the H₂ value chain

hydrogen plants using steam reforming technology

years of experience and leadership in hydrogen production

references with CO2 capture in H2 plants

of existing installed capacity worldwide

- Steam methane reforming (SMR)*

- Auto thermal reforming (ATR)

- EARTH®: Enhanced Annular Reforming Tube for Hydrogen*

- TPR®: Technip Energies Parallel Reformer convective recuperative reformer*

- LSV®: Large-scale Vortex ultra-low NOx burner*

- Dual-chamber process gas boiler

- Our burner test facility in The Netherlands

- CO2 Capture

*Proprietary T.EN technology

- From 5,000 Nm3/h to > 330,000 Nm3/h (grassroot)

- Revamping existing plants

- Increasing existing plant capacity up to 30 percent

- Air Products: LSV burner technology

- Clariant: Structured catalyst EARTH®

- BASF: CO2 absorption

- Shell: CANSOLV capture technology

Key project references

- LG Chem, first BlueH2 by T.EN™ plant to supply Daesan complex in South Korea

- Tallgrass Energy, technology comparison ATR versus SMR enabling >90% CO2 capture – Blue H2

- Sinopec refinery and Acetic Acid facility, China, multi-product HyCO plant with 100% pre-combustion CO2 capture

- HPCL Visakh, India, two hydrogen trains with a combined capacity of 320,000 Nm3/h, comprising the largest hydrogen generation plant in India. The project includes power generation from the hydrogen plant as well as Technip Energies' proprietary recuperative reforming technology TPR (R) that reduces CO2 footprint per unit of hydrogen

- Suncor Refinery, 75 MW power, largest single-train SMR hydrogen plant

- Rosneft Tuapse Refinery, Russia, largest single-train H2 plant in the world, 238,000 Nm3/h

Membership

As a key player in hydrogen solutions and projects, we are a proud member of:

Additional information and downloads

Technology handbook

BlueH₂ by T.EN™ brochure

Side Wall Burner brochure

LSV Burner brochure

EARTH® TECHNOLOGY flysheet

Get in touch

Send a message using the contact us form:

Select Low-Carbon Hydrogen from the Commercial contact per solution dropdown: