Introduction

Hummingbird® ethanol-to-ethylene technology has been selected by LanzaJet, Inc. for a key application which, when combined with LanzaJet’s Alcohol-to-Jet (ATJ) technology, can be used to manufacture sustainable aviation fuel (SAF) using fuel grade bioethanol as raw material.

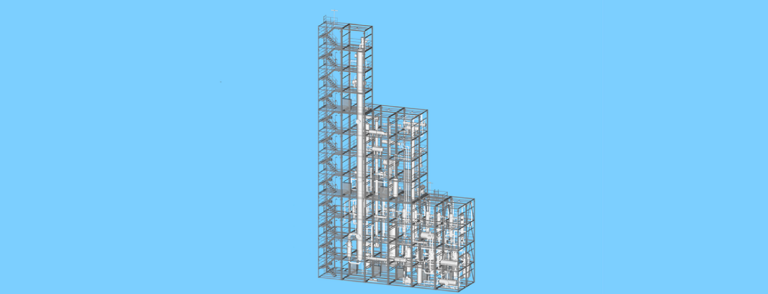

LanzaJet is building their first commercial demonstration scale integrated biorefinery at LanzaJet’s Freedom Pines Fuels site in Soperton, Georgia, USA, that will produce 10 million gallons per year of SAF and renewable diesel starting from sustainable ethanol sources. The facility, which is partially supported with a grant from the US Department of Energy and leverages technology developed by LanzaTech and the Pacific Norwest National Lab (PNNL), will be in production in 2022.

The License and Process Design Packages (PDP) for the project was delivered by the office in Milton Keynes, UK in 2019, with support from the office in Chennai, India. In early 2021, the supply agreement for our proprietary catalyst for the facility was awarded.

Challenge

Commercialising a new chain of technologies

With no commercial reference for LanzaJet’s Alcohol-to-Jet technology and Hummingbird®, the major challenge is appropriate technical and commercial risk mitigation. LanzaJet’s trust in the Hummingbird® E2E technology, paired with Technip Energies providing market leading process guarantees and support, paved the way for this innovative energy transition project that is progressing to realization in 2022.

Technologies

Technip Energies’ Hummingbird® technology provides an efficient, low-cost process for dehydrating bioethanol to ethylene at a polymer grade specification if required. This process step is one of the required process units in LanzaJet’s alcohol-to-jet plant scheme. The Hummingbird® technology was selected among competitors, based on its ability to provide on-spec bioethylene product, as proven in a demonstration plant with over 36,000 hours of operation with an ultra-high selectivity for conversion of more than 99% of the feed ethanol into bioethylene.

Solution

Providing a carbon-efficient, renewable source to make SAF

Ethanol, which can be produced from a variety of locally available energy crops or waste resources, is an ideal substance for the production of sustainable fuels and chemical building blocks. With the Hummingbird® technology there is a carbon efficient pathway to SAF via alcohol-to-jet fuel for a sector in need of reducing their emissions, building resilience and energy security.

Results

The Process Design Packages (PDP) project was delivered on schedule and on budget. The client has now progressed through their final investment decision gate and is progressing with the project EPC, which Technip Energies continues to support in a Licensor advisory capacity, together with proprietary catalyst supply.

Commercial license for Hummingbird®

Gallons per year of SAF and renewable diesel

Get in touch

Do you want to speak directly to our team?

You can browse our locations or send a message using the contact us form, both available on our Contact page.

To discuss Hummingbird® or similar technologies, please select Biofuels from the dropdown below Projects & Solutions.